Sticking to Triumph: The Rise of Hotmelt Adhesive Materials

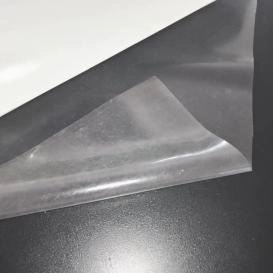

Within the current swiftly changing industrial sector, the need for versatile and high-performing bonding solutions has never been more significant. Introducing thermoplastic adhesive sheets, a groundbreaking innovation that is changing the way sectors approach adhesion challenges. These cutting-edge films deliver a striking mix of durability, pliability, and ease of application, making them a go-to choice for a diverse of fields, from fabrics to technology.

Among the significant innovations in this area are water-resistant TPU thermoplastic adhesive films and clear hotmelt bonding films. These targeted solutions not just elevate the functionality of the completed results but also enable for efficient integration into multiple layouts. As https://www.tomis-hotmelt.com/category/products/hotmelt-adhesive-film/ growing number of manufacturers recognize the value these films bring, the rise in their demand is changing traditional adhesion practices, setting a new benchmark for superiority and efficiency.

Comprehending Hot Melt Adhesive Films

Hotmelt adhesive films constitute novel adhesive solutions which deliver numerous advantages in multiple sectors. These films consist of thermo-responsive polymers that become malleable upon heating, enabling easy application and strong bonding after cooling. As a result, they have gained acceptance in industries like fabric, enclosure, and electronics due to these effectiveness and flexibility.

A notable aspect of hotmelt adhesive films is their potential to create smooth bonds across different surfaces. Moisture-proof Thermoplastic polyurethane hot melt bonding materials, for instance, offer a dependable answer for uses involving resistance to moisture, making them perfect for outdoor gear, protective attire, and various moisture-proof products. Their capacity to resist environmental stressors yet preserving bond integrity represents a required cause for the growing adoption.

In addition to the functional advantages, transparent hotmelt adhesive films address aesthetic requirements within product aesthetics. Such materials deliver strong adhesion without compromising sacrificing the visual appeal of the components that are bonded. This transparency renders them appropriate for purposes in clothing, footwear design, and electronics, where look remains as crucial as effectiveness. As industries continue to change, the rise of hotmelt adhesive films suggests a promising future for cutting-edge adhesive solutions.

Benefits of Waterproof TPU Adhesives

Waterproof TPU thermoplastic adhesive films offer outstanding performance in challenging environments. Their ability to repel water makes them perfect for applications where moisture resistance is critical. This is particularly crucial in fields such as sports apparel, footwear, and automotive, where contact to water can compromise the integrity of the bonded materials. With these adhesives, manufacturers can ensure that their products maintain durability and functionality, even in wet conditions.

Another notable benefit of waterproof TPU adhesives is their strong bonding capabilities. These films adhere well to a range of substrates, including textiles and synthetic surfaces. This versatility allows for greater design flexibility, allowing manufacturers to innovate with different materials without the worry of bond failure. The dependable adhesion not only enhances the overall standard of the end product but also reduces the need for additional bonding solutions, streamlining production processes.

Additionally, waterproof TPU adhesives contribute to enhanced aesthetic qualities in final products. The transparent nature of these films allows for smooth integration into designs, maintaining the visual appeal of the materials they bind. This is particularly beneficial in applications such as fashion and consumer electronics, where appearance is as crucial as performance. The result is a product that not only functions well but also looks great, boosting consumer satisfaction and brand loyalty.

Applications of See-through Hot Melt Films

See-through hotmelt adhesive sheets are commonly used in the cloth and apparel industries due to their ability to bond without affecting the visual appeal of the fabrics. These films offer a smooth adhesive solution for binding labels, appliques, or patches to attire, ensuring a tidy finish that upholds the fabric's design consistency. Their clear application makes them particularly popular in luxury fashion where appearance are crucial.

In the packaging and shipping sector, see-through hotmelt sheets play a crucial role in protecting products while allowing consumers to see the enclosed items. They are often used for fastening and coating tasks, providing a durable bond that boosts package durability. The transparency of these films also acts to improve brand presentation, making the product appealing on retail racks, which is crucial for consumer attraction.

Moreover, these adhesive films find roles in electronics, where transparent adhesion is required for assembling components without obscuring any part of the device. The ability to utilize clear hotmelt films ensures that devices retain their elegant design, providing simultaneously functional and design benefits. This flexibility across various industries highlights the importance of clear hotmelt sheets in current applications.

Emerging Developments in Adhesive Solutions

The bonding sector is witnessing notable progress as producers focus on creating more efficient and sustainable options. The future of hot melt adhesive films is predicted to embrace the combination of sustainable materials, aiming to minimize ecological effects and ensuring excellent efficiency. Advancements in environmentally-friendly and reusable materials will meet rising customer desire for sustainable solutions, making waterproof thermoplastic polyurethane hot melt adhesive materials more desirable across multiple uses.

In addition to that, clarity and aesthetics are emerging ever more critical in bonding film uses. Transparent hot melt bonding films are anticipated to become more popular, especially in sectors where aesthetic appeal is key, such as clothing, auto, and consumer devices. The ability to bond materials seamlessly while ensuring they remain visually appealing can create fresh venues for manufacturers, which leads to improved development and consumer contentment.

Additionally, the rise of smart materials will affect the adhesive technology field. This development includes the development of hot melt adhesive films that can react to external factors, such as temperature or humidity. Such advancements could result in enhanced performance in challenging environments, additionally expanding the application of these films. The persistent exploration of responsive adhesives will propel research and development, leading to a wide array of applications that can change various fields.